Products

Nickel coating

Coated diamond and CBN are used for improving the using efficiency of diamond powder with bonding system.

Titanium coating

Coated diamond and CBN are used for improving the using efficiency of diamond powder with bonding system.

Combined coating

Coated diamond and CBN are used for improving the using efficiency of diamond powder with bonding system.

Chromium coating

Coated diamond and CBN are used for improving the using efficiency of diamond powder with bonding system.

Copper-coating

Coated diamond and CBN are used for improving the using efficiency of diamond powder with bonding system.

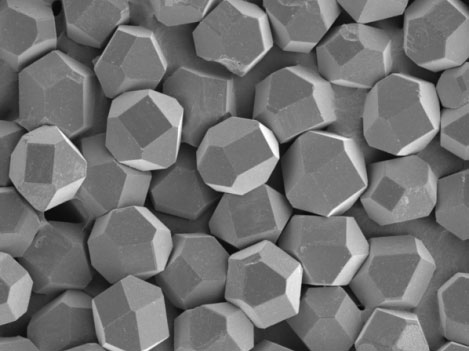

Thermal Conductive Diamond-Ultra

Product introduction:

This product presents a regular cubo-octahedral crystalline form, with extremely low impurity content.

It possesses a very high thermal conductivity coefficient, particle concentration, and product stability.

Size Available: 40um-1300um

Application:

1.Diamond Metal Matrix Composites(DMMC): Cu-Diamond MMC, Al-Diamond MMC and etc.

Thermal Interface Materials(TIM): Thermal gap fillers, Thermal grease and gel, Thermal adhesives, Thermal pad and etc.

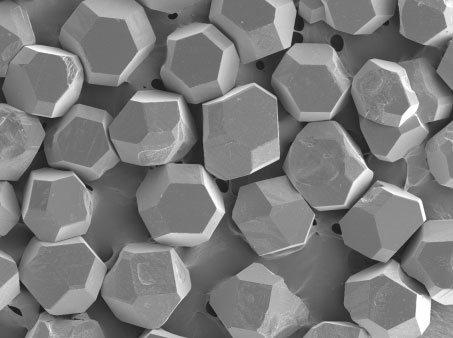

Thermal Conductive Diamond-High

Product introduction:

This product presents a crystalline form close to a cubo-octahedral, with low impurity content and high particle concentration.

It offers high stability and a high thermal conductivity coefficient.

Size Available: 35um-1300um

Application:

1.Thermal Interface Materials(TIM): Thermal gap fillers, Thermal grease and gel, Thermal adhesives, Thermal pad and etc.

2.Diamond Metal Matrix Composites(DMMC): Cu-Diamond MMC, Al-Diamond MMC and etc.

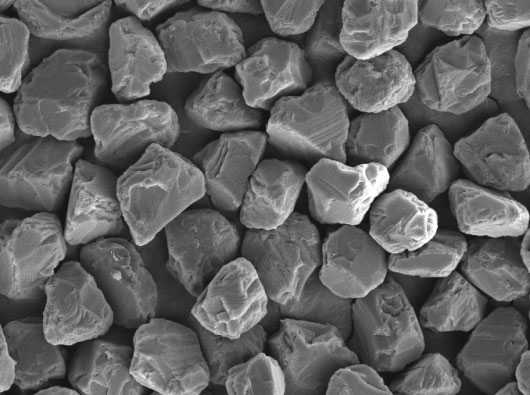

Thermal Conductive Diamond-Economical

Product introduction:

This product features a relatively regular crystalline form, low impurity content, and high particle concentration.

It has high stability and a high thermal conductivity coefficient, making it a preferred cost-effective filler option.

Size Available: 0.02um-350um

Application:

1.Thermal Interface Materials(TIM): Thermal gap fillers, Thermal grease and gel, Thermal adhesives, Thermal putty and etc.

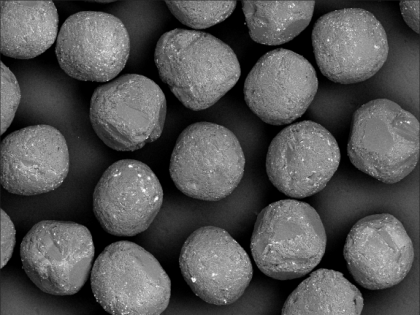

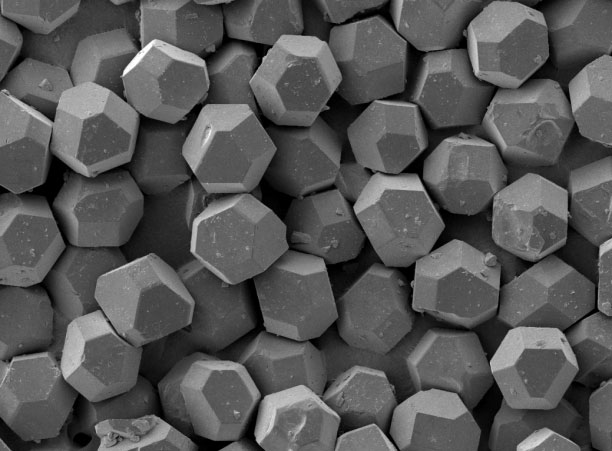

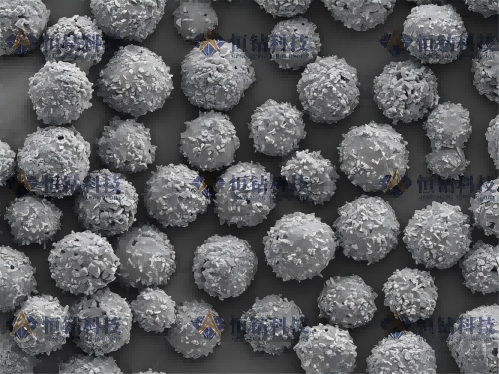

Spherical Diamond

Product introduction:

This product, processed via a special treatment, has a near-spherical crystalline form.

It features a high specific surface area, high particle concentration, low impurity content, good thermal conductivity, high flowability, and easy fillability.

Size Available: 30um-700um

Application:

1.Thermal Interface Materials(TIM): Thermal gap fillers, Thermal grease and gel, Thermal adhesives, Thermal pad and etc.

2.Diamond Metal Matrix Composites(DMMC): Cu-Diamond MMC, Al-Diamond MMC and etc.

Coated Diamond

Product introduction:

This product enhances the stable bonding between metals (such as copper and aluminum, etc) and diamond, reduces interfacial thermal resistance, and thereby improves heat dissipation effectiveness.

Size Available: 1um-1300um

Application:

1.Diamond Metal Matrix Composites(DMMC): Cu-Diamond MMC, Al-Diamond MMC and etc.

2.Thermal Interface Materials(TIM): Thermal gap fillers, Thermal grease and gel, Thermal adhesives, Thermal pad,and etc.

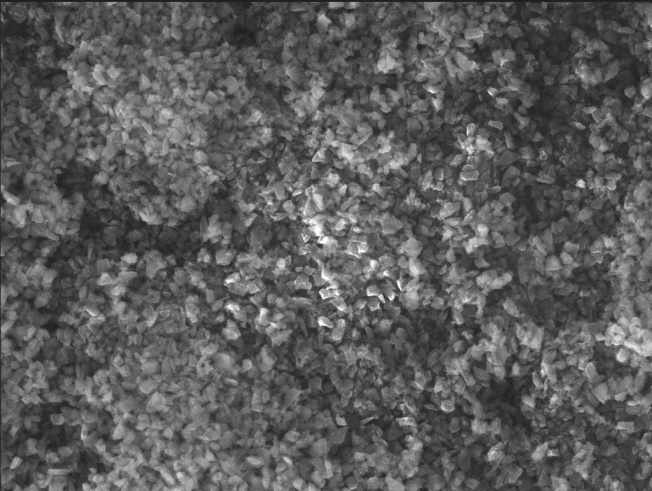

Nano Diamond powder

Product introduction:

Nano-diamond, processed through special treatment, has a high thermal conductivity coefficient, low thermal expansion coefficient, low friction coefficient, and low surface roughness.

Size Available: 50nm-500nm

Application:

1.Diamond Metal Matrix Composites(DMMC): Cu-Diamond MMC, Al-Diamond MMC and etc.

2.Thermal Interface Materials(TIM): Thermal gap fillers, Heat conducting films, Thermal Tape, Phase change material, ultra-thin coating materials and etc.

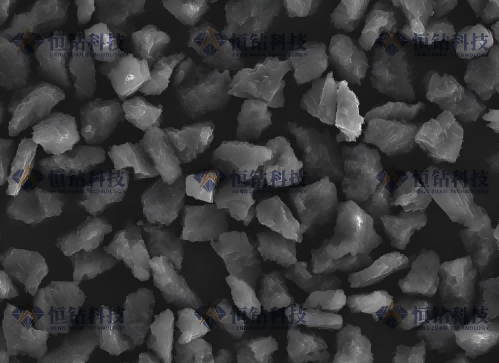

Monocrystalline Diamond

This product, made from high-strength, high-purity diamond, is suitable for processing hard and brittle materials. It delivers excellent grinding and polishing precision while boosting processing efficiency and product yield.

Available Particle Sizes: 0 ~ 500-600μm, etc.

·Regular morphology

·No flake/long particles,

·High surface cleanliness

·Stable performance

Etching Diamond

This product has a honeycomb structure, primarily used in precision grinding and polishing applications—including SiC, sapphire substrate wafers, optics, ceramics, and alloys—and serves as an alternative to polycrystalline diamond.

Available Particle Sizes: 1-3μm ~ 40-60μm

·Strong holding force

·High self-sharpening ability

·Efficient cutting performance

·Significantly reduces workpiece surface roughness

Polycrystalline Diamond

This product is made from explosive detonation. Composed of numerous microcrystals (under 100nm) aggregated by shared crystal planes, It’s suitable for grinding and polishing in semiconductor, optics and other fields.

Available Particle Sizes: 0.1μm ~ 10μm, etc.

·High grinding efficiency

·Strong self-sharpening property

·Low risk of scratching workpieces Etching Diamond

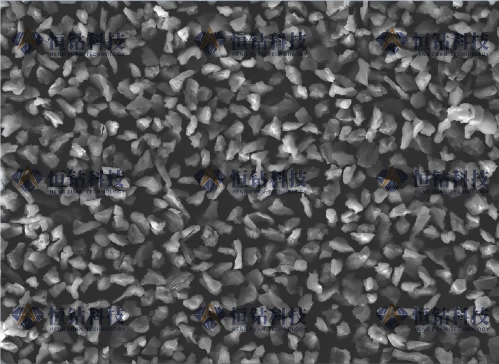

Agglomerated Diamond

The unique multi-edge angle characteristics of agglomerated diamond enable it to produce efficient grinding force during the grinding and polishing process, and can effectively reduce scratches and residual stress on the workpiece surface.

Available Particle Sizes: 0-0.25μm ~ 3-6μm, etc.

·Retains superhardness & offers toughness

·Prevents fine particle loss & poor dispersion

·Reduces workpiece surface scratches effectively

·Lowers residual stress on workpieces

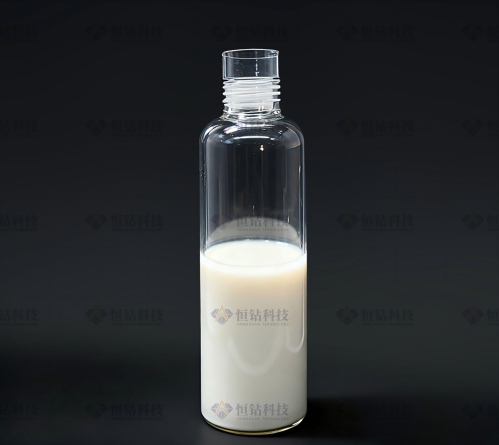

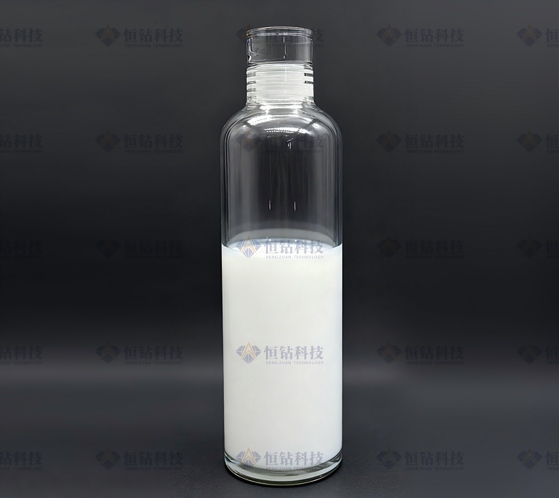

Cerium Oxide Slurry

Our independently developed and manufactured core powders offer stable, controllable quality and high polishing rates, significantly boosting production efficiency while delivering strong cost-effectiveness, making them a preferred industry solution.

Available Particle Sizes: Custom manufacturing to your requirements.

·High polishing speed

·Excellent dispersion stability

·Flexible process adaptation

Aluminium Oxide Slurry

Our independently developed and manufactured aluminum oxide powder offers precisely customizable particle sizes to meet specific requirements. It covers all wafer polishing scenarios, delivering high polishing efficiency to significantly boost production output.

Available Particle Sizes: Custom manufacturing to your requirements.

·High polishing rate

·Flexible customization

·Excellent surface quality

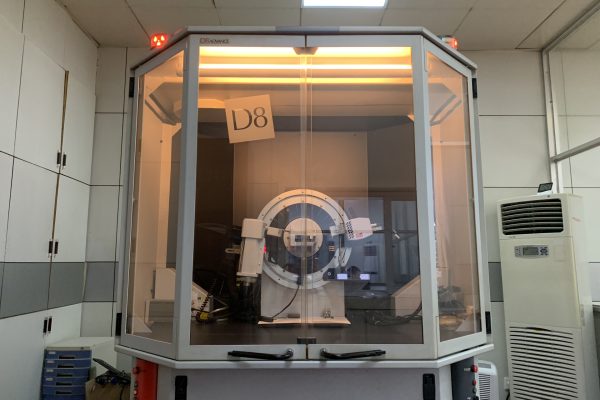

ABOUT

HENGZUAN

Jiangxi HENGZUAN New Material Technology Co., Ltd. is a multi-functional enterprise integrating engineering, science and trade, with legal personality, mainly engaged in production, processing, research and development, import and export and other business, the business scope includes: superhard materials and products, ceramic products, mechanical equipment, etc., the business involves Europe, America, Canada, Southeast Asia and other countries and regions.

Since its establishment in 2000, the company has always adhered to the concept of "one-day commitment, trustworthy for a hundred years", committed to the development and management of diamond abrasives and products, firmly took the road of professional development, and cast its own brand.

Advantages

The company has established a sound and complete quality management system and has passed the ISO9001 international quality system certification

ISO9001 international quality certification

It has established a sound and complete quality management system and passed the ISO9001 international quality system certification

Cast your own brand

It has established a sound and complete quality management system and passed the ISO9001 international quality system certification

Committed to diamond abrasives and products

Since its establishment in 2000, the company has always adhered to the concept of "one-day commitment, trustworthy for a hundred years"

Customer first, create brilliance together

The company pursues the corporate tenet of "people-oriented, quality first, customer first, and create brilliance together"

Certificates

NEWS

Yu Diamond: It is planned to promote a 500 million yuan employee stock ownership plan

Let's first briefly understand what the ground source heat pump is, the ground source heat pump is a new energy utilization technology that uses shallow ground energy for heating and cooling...

Yu Diamond: It is planned to promote a 500 million yuan employee stock ownership plan-2

Let's first briefly understand what the ground source heat pump is, the ground source heat pump is a new energy utilization technology that uses shallow ground energy for heating and cooling...

Yu Diamond: Plans to launch a 500 million yuan employee stock ownership plan-3

Let's first briefly understand what the ground source heat pump is, the ground source heat pump is a new energy utilization technology that uses shallow ground energy for heating and cooling...

- 工厂电话:0799-3426666/13319526689

- 地址:江西省萍乡市湘东区下埠镇陶瓷工业园(江西恒钻新材料科技有限公司)

- 邮箱:info@hengzuantech.cn